A circuit breaker which used vacuum as an arc extinction medium is called a vacuum circuit breaker. In this circuit breaker, the fixed and moving contact is enclosed in a permanently sealed vacuum interrupter. The metallic bellows made of stainless steel is used to move the moving contacts. The design of the metallic bellows is very important because the life of the vacuum circuit breaker depends on the ability of the component to perform repeated operations satisfactorily.

Table of Contents

vacuum circuit breaker

A circuit breaker which used vacuum as an arc extinction medium is called a vacuum circuit breaker. In this circuit breaker, the fixed and moving contact is enclosed in a permanently sealed vacuum interrupter. The arc is extinct as the contacts are differentiated in high vacuum. It is generally used for medium voltage ranging from 11 KV to 33 KV. The vacuum circuit breaker has a high insulating medium for arc extinction as compared to the other circuit breaker.The pressure inside the vacuum interrupter is approximately 10-4 torrent and at this pressure, very few molecules are present in the interrupter.

construction of vacuum circuit breaker

It is very simple construction as compared to any other circuit breaker. Their construction is mainly divided into 3 parts, i.e., fixed contacts, moving contact and arc shield which is placed inside the arc interrupting chamber.

The outer envelope of the vacuum circuit breaker is built up of glass because of the glass envelope help in the examination of the breaker from outside after the operation. If the glass becomes milky from its original finish of silvery mirror, then it indicates that the breaker is losing vacuum.

The fixed and moving contacts of the circuit breaker are placed inside the arc shield. The pressure in a vacuum interrupter at the time of sealing off is kept at about 10-6 torr. The moving contacts of the circuit breaker are moved through a distance of 5 to 10 mm depending upon the operating voltage.

The metallic bellows made of stainless steel is used to move the moving contacts. The design of the metallic bellows is very important because the life of the vacuum circuit breaker depends on the ability of the component to perform repeated operations satisfactorily.

working of vacuum circuit breaker

When the fault happens within the system, the contacts of the fuse area unit captive apart and therefore the arc is developed between them. once the current-carrying contacts area unit force apart, the temperature of their connecting components is incredibly high thanks to that ionization happens. Due to the ionization, the contact space is filled with the vapour of positive ions which is discharged from the contact material.

The density of vapour depends on the current in the arcing. Due to the decreasing mode of current wave their rate of the salvation of vapour fall and after the current zero, the medium regains its dielectric strength provided vapour density around the contacts reduced. Hence, the arc doesn’t restrike again because the metal vapour is quickly removed from the contact zone.

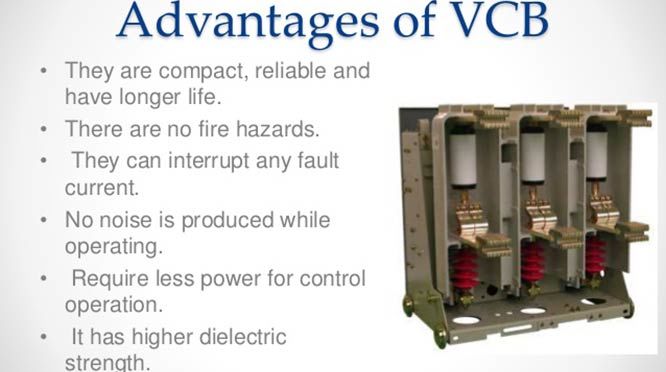

advantages of vacuum circuit breaker

Vacuum offers the utmost insulating strength. So it has extreme superior arc quenching features than any other medium.

- The vacuum circuit breaker has a long life.

- Unlike Oil Circuit Breaker or air blast Circuit Breaker, the explosion of VCB is avoided. This enhances the safety of the operating personnel.

- No fire hazard

- The vacuum circuit breaker is quickly in operation so ideal for fault clearing. A vacuum circuit breaker is suitable for repeated operation.

- Vacuum circuit breakers are almost maintenance-free.

- Gas isn’t exhausted to the atmosphere and Noiseless operation.

disadvantages of vacuum circuit breaker

- The main disadvantage of vacuum circuit breaker is that it is uneconomical at voltages exceeding 38 kvolts.

- The cost of the breaker becomes exceeding at higher voltages. This is due to the fact that at high voltages (above 38 kV) more than two(2) numbers of the circuit breaker are required to be connected in series.

- Moreover, VCBs production is uneconomical if produced in small quantities.

application of vacuum circuit breaker

The vacuum circuit breaker is today recognized as the most reliable current interruption technology for medium voltage switchgear. It requires minimum maintenance compared to other circuit breaker processing.

The technology in the mains especially principal appropriate for mainly medium voltage application. For higher voltage vacuum technology has been exhibited, however, it’s not commercially possible. Vacuum circuit breakers area unit utilized in metal-clad Switchgear and additionally in ceramic warehoused circuit breakers.

Thus, this is all about Vacuum Circuit Breaker (VCB) working and applications. We hope that you have got a better understanding of this concept. If there is a problem, please let me know in the comment box.

Owner Of ICEEET

1 comment

[…] Vacuum Circuit Breaker […]