A French physicist namely “Breguet” was famous for his effort in the initial days of telegraphy. He suggested the utilization of reduced part of conductors to guard telegraph stations against the hits of lighting with liquefying, the slighter wires would guard equipment along with wiring in the building. In the year 1864, lighting installations and telegraph cables can be protected by employing a variety of foil fusible essentials and wires. Finally, Thomas Alva Edison has patented a fuse as an element of his electric distribution system in the year 1890. This article discusses what is a fuse, types of fuses and its applications in various fields.

Table of Contents

What is a fuse?

A fuse is an electrical safety device built around a conductive slice that is designed to melt and separate in the event of obsessive current. Fuses are constantly connected in series with the component(s) to be saved from extending current, so that when the fuse blows it will open the entire circuit and stop current through the component(s). A fuse connected in one branch of a parallel circuit, obviously, would not affect current through any of the other branches.

A fuse is a short piece of metal, inserted in the circuit, which melts when excessive currents flow through it and thus breaks the circuit.

The fuse element is generally made of materials having a low melting point, high conductivity and least deterioration due to oxidation e.g….silver, copper, etc.

ADVANTAGES

- It is the cheapest form of protection available.

- It requires no maintenance.

- Its operation is inherently completely automatic, unlike a circuit breaker which requires expanded equipment for automatic action.

- It can break bulky short-circuit current without noise or smoke.

- The inverse time-current characteristic of a fuse makes it suitable for extending current protection.

- The minimum time of function can be made much shorter than with the circuit breakers.

DISADVANTAGES

- During short circuit or overload once fuse blows off replacing of fuse takes time. During this period the circuit lost power.

- When fuses are connected in series it is difficult to discriminate the fuse unless the fuse has a significant size difference.

Desirable Characteristics Of Fuse Element

Fuse Element Materials:

The material used for fuse elements ought to be of low melting point, low ohmic loss, high conductivity, low cost and free from detraction. The material used for making fuse material has a low melting point such as tin, lead, or zinc. A low melting point is, but, available with a high specific resistance metal shown in the table given below.

The material mainly used for fuse element are tin, lead, silver, copper, zinc, aluminum, and a shaft of lead and tin. A shaft of lead and tin is used for small current rating fuses. For current exceeding 15A, this shaft is not used as the diameters of the wire will be larger and after fusing the metal released will be exceeding.

Beyond, 15A rating circuit, copper wire fuses are utilized. Copper wire suffers from the drawbacks that it operates at rather warm temperature if a fairly low fusing issue is desired. There is, therefore, a trend for the wire to overheat with the result that its cross-sectional space and fusing current square measure bit by bit reduced, and premature melting of the wire could occur.

Silver is mainly used as a fuse element because it has the following advantages

- It doesn’t get oxidized, and its oxide is unstable.

- The conductivity of silver doesn’t deteriorate with oxidation.

- payable to its high conductivity the mass of molten metal to be handled is minimized and thus operating speed is fast.

But silver is very costly as compared to other metals thereby copper or an alloy of lead-tin is mostly used as a fuse wire. Zinc in strip form only is also used as a fuse element because it does not melt very quickly with a small overload.

Important Terms Of Fuse:

Following are some of the significant and frequently used term used in Fuse.

Minimum Fusing Current:

It is the worth of current flowing through the Fuse wire at that the Fuse wire can soften.

Fuse Rating:

The fuse rating is given in Ampere. It is generally that value of current at which the Fuse is expected to operate safely without melting. This value of current will definitely be less than the Minimum Fusing Current.

Fusing Factor:

Fusing issue is outlined because the magnitude relation of minimum fusing current to the fuse rating.

Fusing Factor = Minimum Fusing Current divided by Fuse Rating

The value of Fusing Factor is always greater than one 1.

Prospective Current:

Expected Current of Fuse is the value of current which will flow through it just before the melting of the fuse wire under Short Circuit rule.

Melting Time / Pre-arcing Time:

This is the time taken by a fuse wire to be broken by melting. It is counted from the instant; the overcurrent starts to flow through the fuse, to the instant when fuse wire is just broken by melting.

Arcing Time:

After breaking of fuse wire there will be an arcing between both melted point of the wire which will be mitigated at the current zero. The time from the instant of arc initiated to the instant of the arc being extinguished is known as Arcing Time of the fuse.

Total Operating Time:

Total Operating Time of Fuse is the addition of Pre-arcing and arcing time.

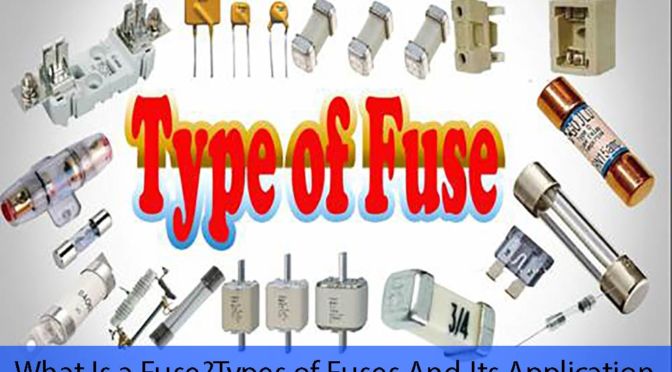

Types of Fuses:

Low Voltage fuse:

Fuse is a current interrupting device which breaks or opens the circuit by fusing the element when the current in the circuit exceeds a certain value. Fuses are mainly categorized into two types, i.e., High voltage fuses and Low voltage fuses. Low voltage fuses can also divide into two types, namely semi-enclosed or rewirable type and entirely enclosed cartridge type.

Rewirable Fuses

Rewirable fuses are most commonly used in housing wiring and little current circuits. It is also known as a kit – kat fuse. It has a porcelain base which is carrying the fixed contact through which the live wires are connected. The fuse carrier is the independent part which is easily removed or stuck in the base.

The fuse element is built of lead, tin, copper or alloy of tin-lead. The current required for melting the fusing element is as much again the value of normal operating current. If more than two or three fuse elements are used in the fuse, then they should be kept away from each other. The de-rating factor of the fuse element is 0.7 to 0.8. When the fault occurs, the fuse element is melt, and the circuit is interrupted.

The melting fuse element takes out of the fuse, and the new one replaces it. The supply is continuous by reinserting the fuse in the base. The rewirable fuse has the advantages of replacement of fuse element except any risk. The cost of the replacement is also very less.

The following are the inconvenience of the rewirable fuse.

Unreliable Operation – For the working of the fuse it is essential to choose the element of suitable size. The element becomes decay because of the oxidation. The oxidation occurs because of the continuous heating of the element.

Low rupturing capacity –The breach capacity of the fuse is limited. For example, the 2kA is the breaking capacity of the fuse whose normal current capacity is 16A. And fuse whose normal current capacity is 200A, their breach capacity is 4kA.

Slow Speed of Operation – The arcing time of the fuse is very highly. And the additional source isn’t used for extinction the arc.

The risk of Flame and Fire – Because of the rewirable facility the inexpensive wire is used for the protection of the devices against the short circuit and overload.

Cartridge or High Rupturing Capacity Fuses:

The form of the fuse is made of steatite. The steatite is the powder of the mineral. often the ceramic material is used in the fuse because they had good mechanical strength. The brass cap holds the fuse material in the fuse. The brass caps are fixed on the ceramic part. It is fixed by using the particular force so that the fuse can withstand high pressure.

The ending contacts of the fuse are welded on the metallic cap. The powder of quartz is filled between the fuse material and the cartridge body of the fuses. This powder act as an arc mitigated medium in the fuse.

The powder of quartz absorbs the heat which induced because of the shortcircuit current. Then absorbing the heat, the quartz is converted into the lead which opposes the restriking voltage.

The fuse element is built of silver or copper. It is linked by mean of the tin joint. The tin joint monitoring the temperature of the fuse from the short-circuiting current. The melting point of the silver is 980ºC while the melting point of tin is 240ºC. When the fault occurs in the system, the short-circuit current first passes through the tin. The tin prevents the shortcircuit current to flows through the silver.

Advantages:

1. They are capable of clearing high as well as low fault currents.

2. They do not deteriorate with age

3. They have a high speed of operation

4. They require no maintenance

5. They permit cosistence performance

Disadvantages:

- They have to replaced after each operation

- The heat produced by the arc may affect the associated switches.

HRC Fuse with Tripping Device:

When a fuse blows out the tripping device during the fault state, it will cause the circuit breaker to operate. The body of a fuse is made of ceramic material with a metallic cap fixed at each end. They are connected by a series of silver fuse elements. There is a plunger at one end, which hits the tripping mechanism of circuit breaker under fault conditions, which leads it to operate the circuit. The plunger is connected through a fusible link and a tungsten wire to the other end of the cap.

As fault occurs, the first element to be blown out is silver fuse and current is shifted to tungsten wire. The travel of the plunger is set in such a way that is not ejected from the fuse body during fault conditions.

Advantages of HRC Fuse with Tripping Device:

- During single-phase fault on a three-phase system, the plunger trips the circuit breaker, which opens all the three phases, i.e. it prevents single-phase supply as well.

- The effects of the short circuit need to be considered in the circuit breaker, which allows the use of an inexpensive circuit breaker.

- The fuse-tripped breaker is capable of dealing with little currents, which avoids the necessity of replacing the fuse.

High Voltage Fuse:

All types of high voltage fuses are used upon the rated voltage up to 1.5 Kv to 138 Kv. High voltage fuses are used to safe the instrument transformers & small transformers. It is built up of silver, copper & tin. When the heat generated, the arc produces which causes the boric acid to evolve high amount of gases. That’s why these are used in outdoor places.

These are of three types which are as follows:-

- Cartridge Type HRC Fuses:- It is similar to low voltage type, only some designing character are different.

- Liquid Type HRC Fuses:- These are used for circuit up to 100A rated current& systems up to 132Kv. These fuses have the glass tube filled with carbon tetrachloride. The one end of the tube is packed and another is fixed by phosphorous bronze wire. When fuse function starts, the liquid uses in the fuse extinguish the arc. This increase the short circuit capacity.

Applications of Different Types of Fuses:

The different types of fuses and their uses have discussed are essential components in all the electrical circuits. Some of the main applications of fuses in the Electrical and Electronics field include the following.

- Power Transformers

- Electrical Appliances, like ACs (Air Conditioners), TV, Washing Machines, Music Systems, and

- many more.

- Electrical Cabling in Home

- Mobile Phones

- Motor starters

- Laptops

- Power Chargers

- Cameras, Scanners, Printers, and Photocopiers

- Automobiles, electronic devices and Gaming’s

From the above information, finally, we can conclude that fuse and their types explained. The main function of the fuse is to protect the electrical circuits from the overflow of current. In a real-time situation, the flow of current during the wires may not be consistent all the times. In those situations, the device may get damaged from overheat. While the equipment has highly developed with the handling of a circuit breaker, these types of fuses are still employed in various places like fundamental electrical components. Here is a question for you, what are the uses of a fuse?

Owner Of ICEEET

4 comments

[…] What Is a Fuse? Types of Fuses And Its Application. […]

[…] What Is a Fuse?Types of Fuses And Its Application. […]

[…] What Is a Fuse?Types of Fuses And Its Application. […]

Asking questions are truly good thing if you are not understanding anything completely, except this article presents good understanding even.|